|

Qingdao Luckyia Import & Export Trade Co.,Ltd.

|

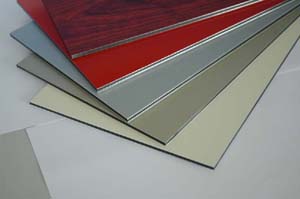

Aluminum Composite Panel

| Payment Terms: | T/T L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Min. Order:1000 pcs;Packing:wooden case;PaymentType:T/T L/C;Trademark:Lucky;ExpRegion:All over the world;

■ Features: ■ Light, even, convenient color selection, impact resistance, efflorescence resistance, easily maintaining, heat and sound isolation, perfect inflammable retardant performance, convenient for constructing. ■ The product is suitable for the following engineering: Indoors and shop front decoration, ceiling, walls, building screen walls, advertisement signboard, counter, furniture, auto, internal and external ship decoration. ■ Standard specification: (MM) Thickness (T) Width (W) Length (L) 1-3 1220 2440 4-6 1220 2440 4-6 1250-1270 2440-3099 Clients can order the plate of various length according to the actual requirements. Our company also produces plates with special color according to client’s requirement. Technology Support Basic level management 1. Plaster the exterior wall for 15 mm, level the wall with 1:3 cement mortar. 2. Brush a layer asphalt erosion resistance on the wall surface. Frame installation 1. According to the spec and decoration requirement of aluminum composite panel, draw the detailed position of vertical and horizontal frame keel line on the leveling surface. For high buildings, the therodolite is needed for controlling and correction. 2. On both sides of vertical frame keel, according to the distance between of 450-500MM, drive the steel expansion bolt into the angle iron. The horizontal frame L50×50×2MM angle iron is fixed on the vertical frame keel. When the vertical size of the board is larger than 1500MM, fix it according to vertical frame keel fixation method. Aluminum composite panel installation 1. Fix the aluminum composite panel with the 400-500MM angle aluminum, which is 50MM long and the distance between is 120×20×2MM, and rivet. 2. Fix the angle aluminum which is on the tapping bolt aluminum composite panel on the frame keel. A gap of 20MM should be left between two aluminum composite panels. 3. Fill the plastic mat in the board gap and seal it with climate resistant glue.

Related Search

Aluminum Plastic Composite Panel

Fireproof Aluminum Composite Panel

Pvdf Aluminum Composite Panel

Aluminum Composite Panel Plastic

Polyester Aluminum Composite Panel

Aluminum Composite Plastic Panel

More>>